While computer numerical control technology is most often associated with precision machining systems like mills and lathes, CNC integration has likewise transformed custom metal forming and bending services – most notably in the form of CNC panel bending and press brakes.

Nevertheless, all of these manufacturing processes see the same basic benefits compared to manual metalworking methods: higher precision, accuracy, and repeatability combined with the speed and efficiency of automation.

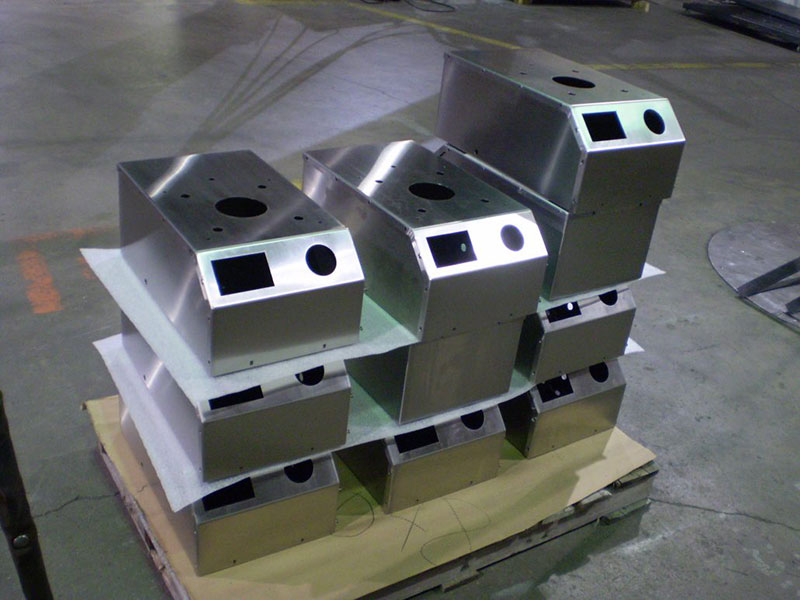

At DMG, we integrate advanced CNC panel bending and press brake technology to produce superior quality parts that meet our customers’ exacting specifications.

CNC Bending and CNC Forming Processes at DMG:

- CNC Panel Bending – Our CNC panel benders and folding machines use precision-based software to program and control the bending apparatus, ensuring high accuracy and repeatability in all angles and dimensions. That provides more freedom in complex design combined with a higher degree of repeatability.

CNC systems automatically adjust to various panel sizes and shapes, accommodating multiple bends in a single operation. That allows us to reduce setup time and the associated labor costs, further maximizing efficiency in production. Our facility’s integration of automatic loading and unloading systems further improve productivity and throughput, as well as worker safety.

- CNC Press Brakes – CNC press brake systems integrate a press mechanism, a punch (top tool), and a die (bottom tool), all working in conjunction to create precise bends in sheet metal with an extremely high degree of accuracy and repeatability. The CNC software programs the bending sequence, angle, depth, and material positioning, maintaining high-precision bending operations from the next, especially beneficial in the case of complex part features and geometries.

The Advantages of CNC Metal Forming

DMG’s CNC metal forming systems achieve close-tolerance results in complex metalworking operations. Every cycle is thus performed as quickly, efficiently, and consistently as possible. While a highly skilled operator working with manual forming tools could achieve similar results for many jobs, manual processes typically require much more time, and thus labor costs.

Crucial to many mid-volume and high-volume runs, manual forming operations can’t match the speed and capacity of our CNC bending and press brake systems. In terms of speed, the advantages of DMG’s CNC metal forming systems are twofold: we can meet your requirements for rapid turnaround and/or high-volume orders seamlessly.

Quality American Metalworking Services for the Midwest and Beyond

DMG combines state-of-the-art CNC equipment with superior craftsmanship to tackle your custom fabrication project from product development to final delivery. Our consistent results have established DMG as one of the leading contract manufacturers serving the Indiana region, the greater Midwest, and beyond.